Business models: Producing laminated safety glass

At the very end of the manufacturing chain, the production of laminated safety glass has a very high share in the value creation.

Customer satisfaction is also significantly influenced by the company's ability to deliver.

Whether laminated safety glass made of toughened glass, a complex designs, SGP multilayer laminates, switchable and other functional glass, there are no limits to the possibilities.

Not all laminated safety glasses are the same.

Due to the different applications of this product class, different manufacturers with different requirements have emerged.

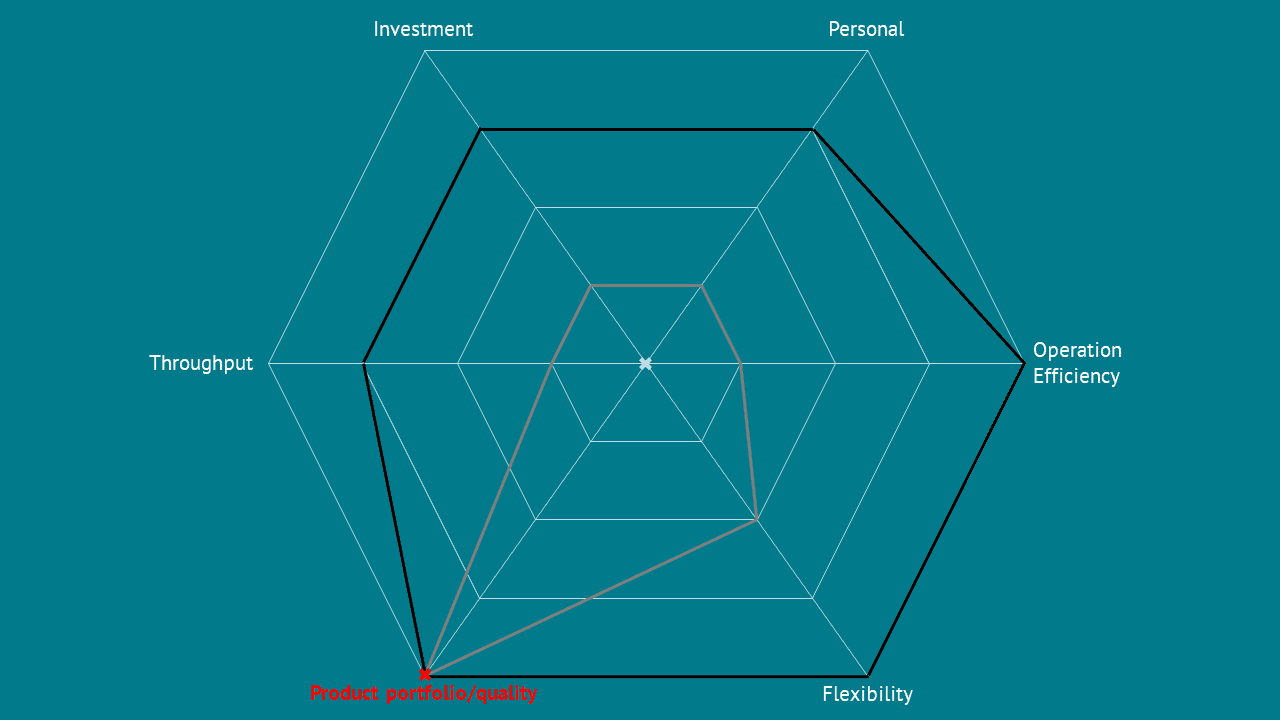

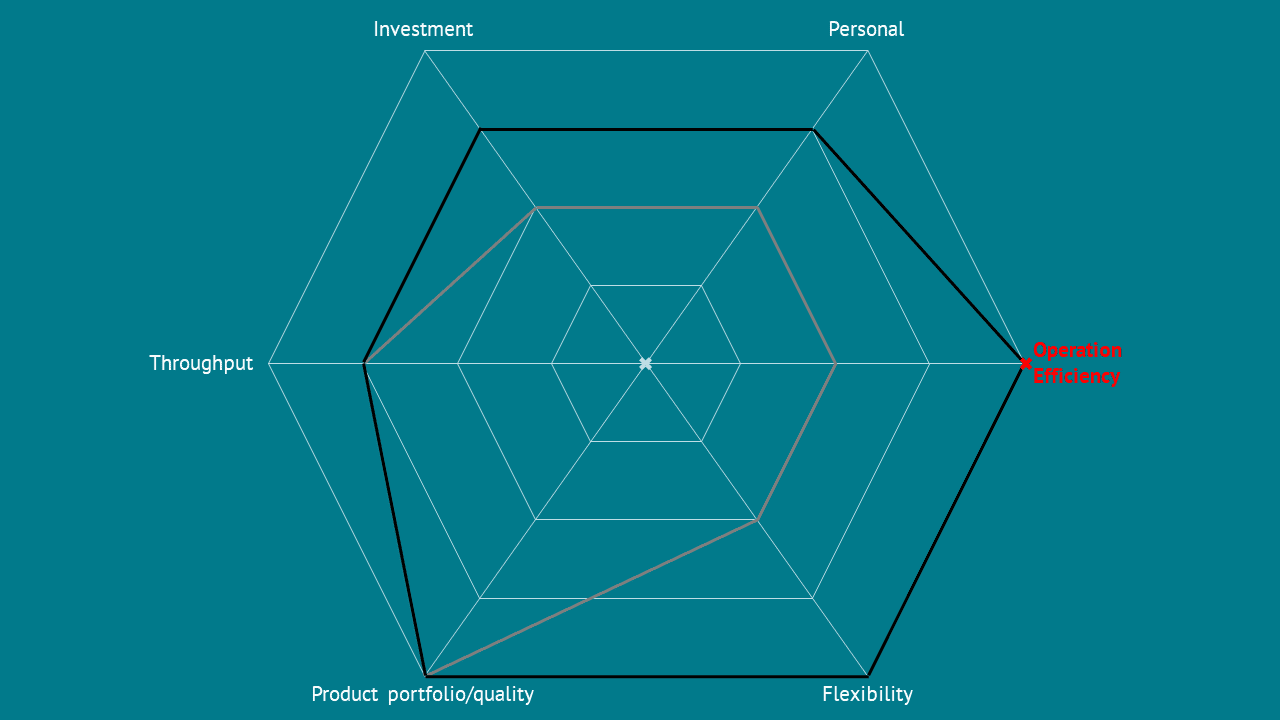

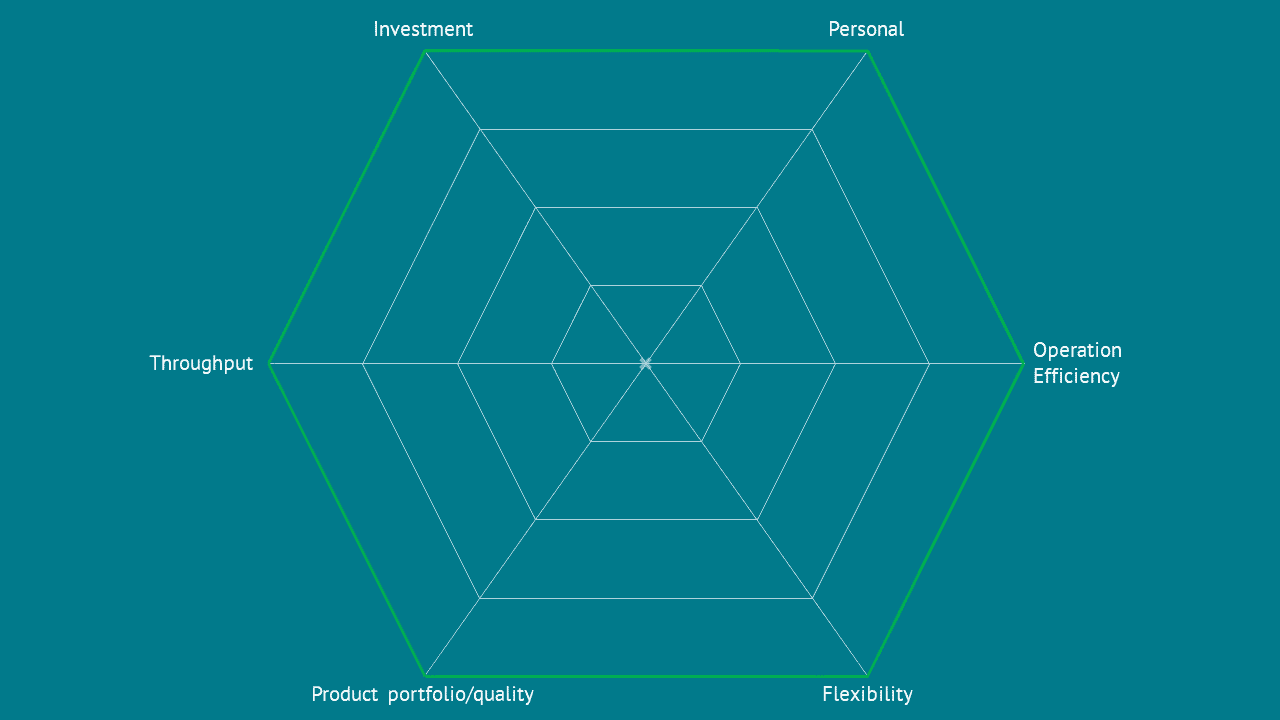

Which lamination system is suitable for which application is shown graphically in the following diagrams.

Manufacturer of special products - in this example: Glassbel Lithuania

Demand:

- 20-50 sqm laminated glass per day

- Special products such as switchable glasses, multilayers, etc.

Situation:

- Product portfolio currently only possible with vacuum bags

- Right timing required:

- Modernization, capacity expansion, new building planning

Solution:

Upgrade of existing infrastructure with LAMIPRESS®

Mass production of laminated safety glass

Demand:

- Large format basic laminates (2×4 with PVB).

- From 1,000 to 10,000 sqm per day per line

Situation:

- Autoclave with nip-roll line is the method of choice

LAMIPRESS® does not offer a suitable solution

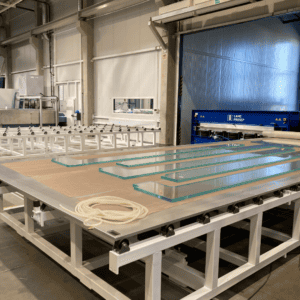

Small to medium-sized companies - in this example: Lippische Glasveredelung Bastian GmbH

Demand:

- 50-100 sqm per shift

- Laminated safety glass from toughened glass of own production

- Fix-sized laminates in various sizes, geometries, etc.

Situation:

- Autoclave too large, slow, inflexible, expensive

- Autoclave-free systems technically too limited

Solution:

LAMIPRESS® in manual version e.g. with 3x4m usable area

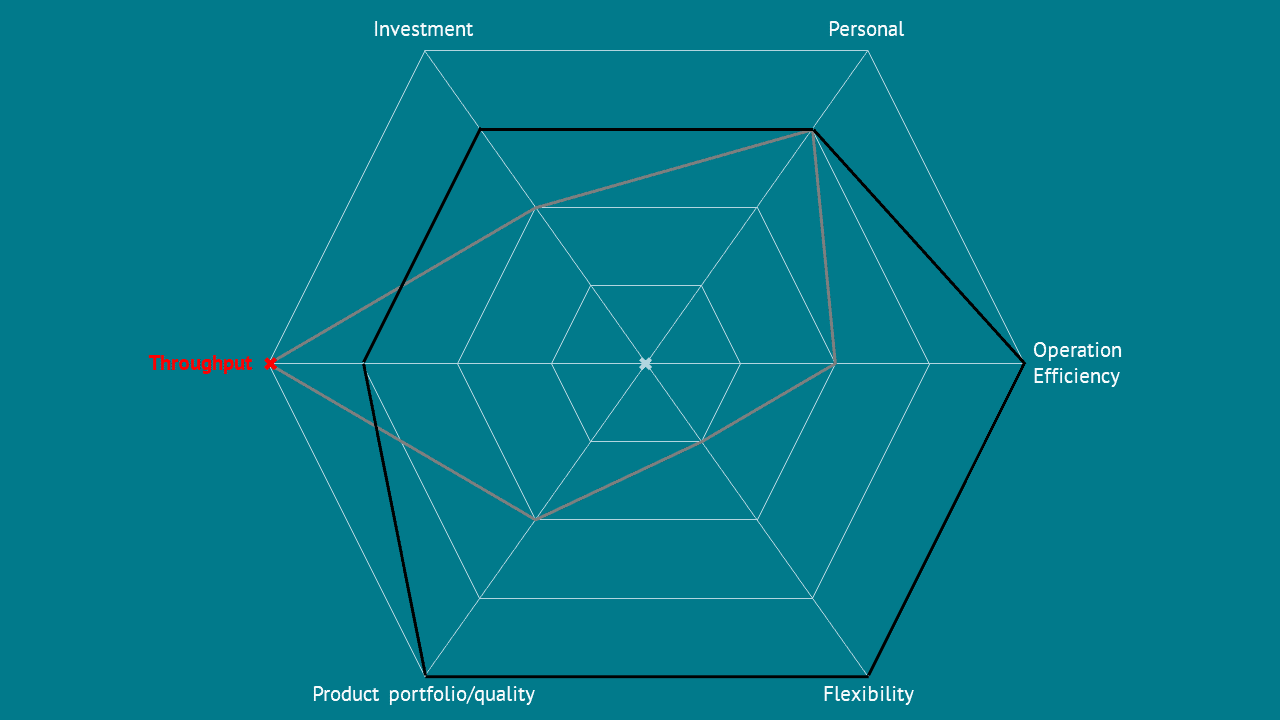

Medium-sized companies to corporate groups - in this example: Flachglas Nord-Ost GmbH

Demand:

- Process-safe production of the existing product range

- Throughput of 100-200T sqm laminated safety glass per year

- Most efficient use of each sqm of hall space

Situation:

Usually existing autoclave with nip-roll plus vacuum bags

Alternative:

- LAMIPRESS® in jumbo size with LamiStore up to 400 sqm per day

- With LamiDoublePress up to 800 sqm per day possible

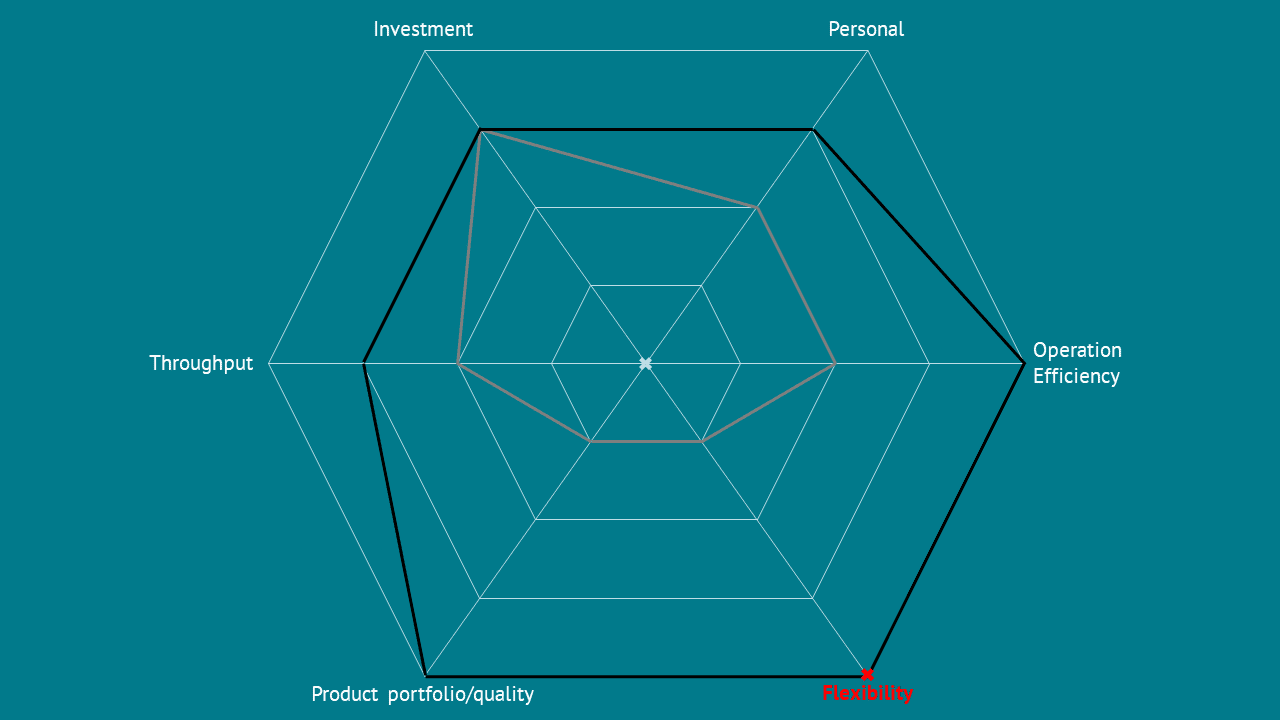

LAMIPRESS® and autoclave symbiosis - The best of both worlds

Situation:

- Series production with the nip-roll line

- Special products in the same autoclave with vacuum bags

Problem:

- Everything from 2x10 mm inhibits the productivity

Solution:

- Combination of LAMIPRESS® and autoclave.

- Saving the manpower of the vacuum bag building

- Highest flexibility, efficiency, delivery speed

- LAMIPRESS® ensures less than 1% rejection rate for complex products

- Additional capacity of 30% only at the basic glass line